WELCOME TO THE BRUNSWICK CROWN PATTERN ZONE

The Crown Pattern Zone (CPZ) allows owners and operators to download and use patterns for various leagues, tournaments, and events. To use the Pattern Library, follow the steps below.

STEP 1: BROWSE AND DOWNLOAD PATTERNS

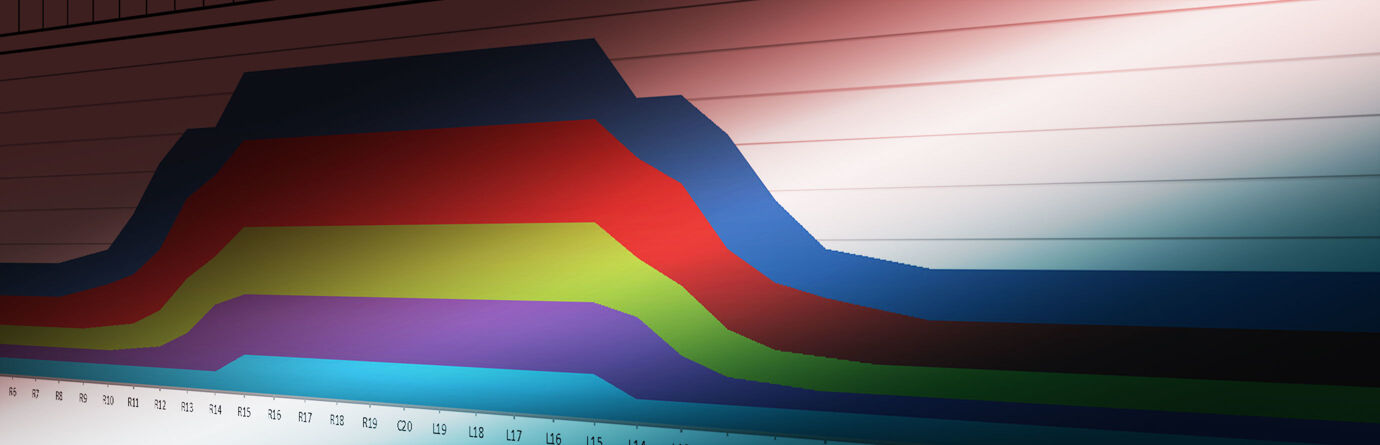

The CPZ is categorized into Gold Crown Patterns and Red Crown Patterns. Gold Crown Patterns are a collection of featured patterns. Each pattern is designed to offer specific scoring levels and pattern transitions while limiting the style of the player with the most significant advantage. Gold Crown Patterns are excellent for various league and tournament formats.

STEP 2: MANAGE PATTERNS

Open Pattern Manager from your computer and import patterns. Your patterns are now available for use on your lane machine! Edit and create your own lane patterns for the ultimate customization. Pattern Editor allows you to build your own library or track pattern adjustments.

BROWSE AND DOWNLOAD PATTERNS

The proof is in the pattern. Choose from our library of tournament and league-ready favorites or build your own! So many patterns, so little time. Find yours today!